Additive Manufacturing Systems

Manufacturing dominated by “material subtraction” saw a sign change in 1987 with the advent of 3D printing, also known as Additive Manufacturing (AM) and Rapid Prototyping (RP). 3D printing realizes complex objects in layers directly from their CAD definitions.

Its primary benefit is "total automation" which helps in rapid launch of new products ahead of competition. It offers benefits such as excellent geometric and material complexities. 3D Printing has come a long way in terms of materials, quality and process capabilities.

We at ZBT Mechanics LLP, in association with RM Lab, Dept. of mechanical Engineering, IIT Bombay are actively involved in design and development of Rapid manufacturing techniques such as cladding, layered Sand sintering and Lasers, CMT arc welding and Electron beam welding methods.

Our Research Areas and Products :

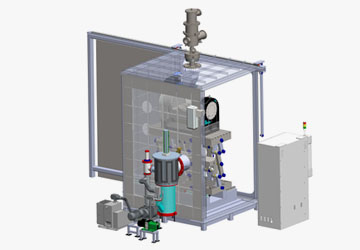

- Powder bed 3D printing using Laser Sintering process with CNC controlled Linear motors achieving speeds upto 180 mtrs/mins and acceleration upto 20G

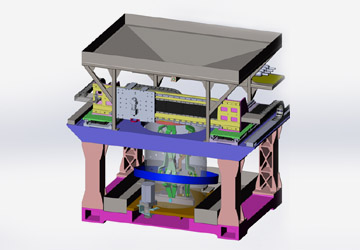

- 5 Axis hybrid manufacturing system with Laser gun and milling heads

- 5 Axis hybrid manufacturing systems with Electron beam welding (EBHM) using wire and powder

- Arc welding based layered manufacturing (Arc HLM) using 6-Axis articulated robot