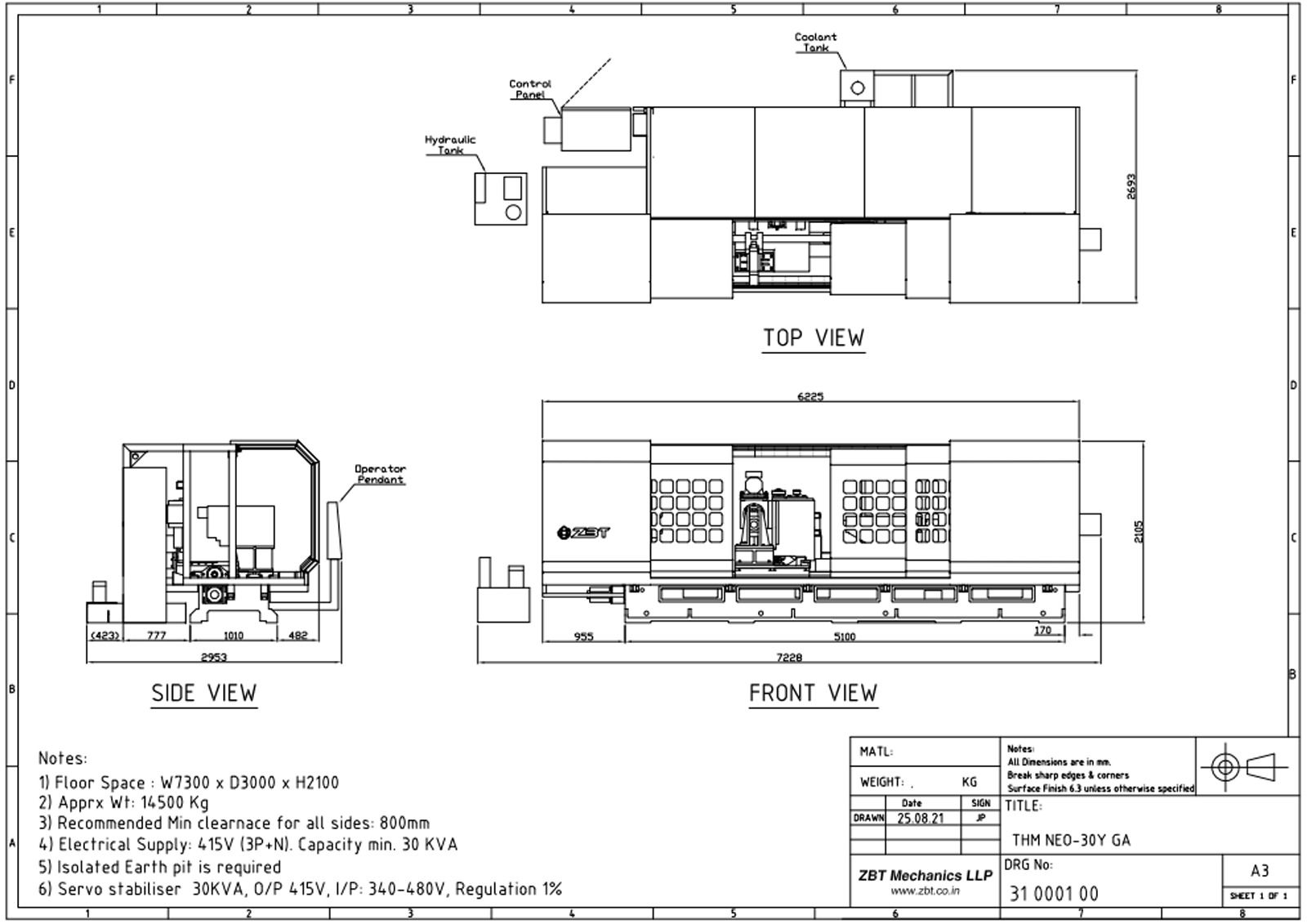

THM-Neo Series

The New generation Thread Milling...

Horizontal Thread Milling with 3 & 4 Axes Configuration

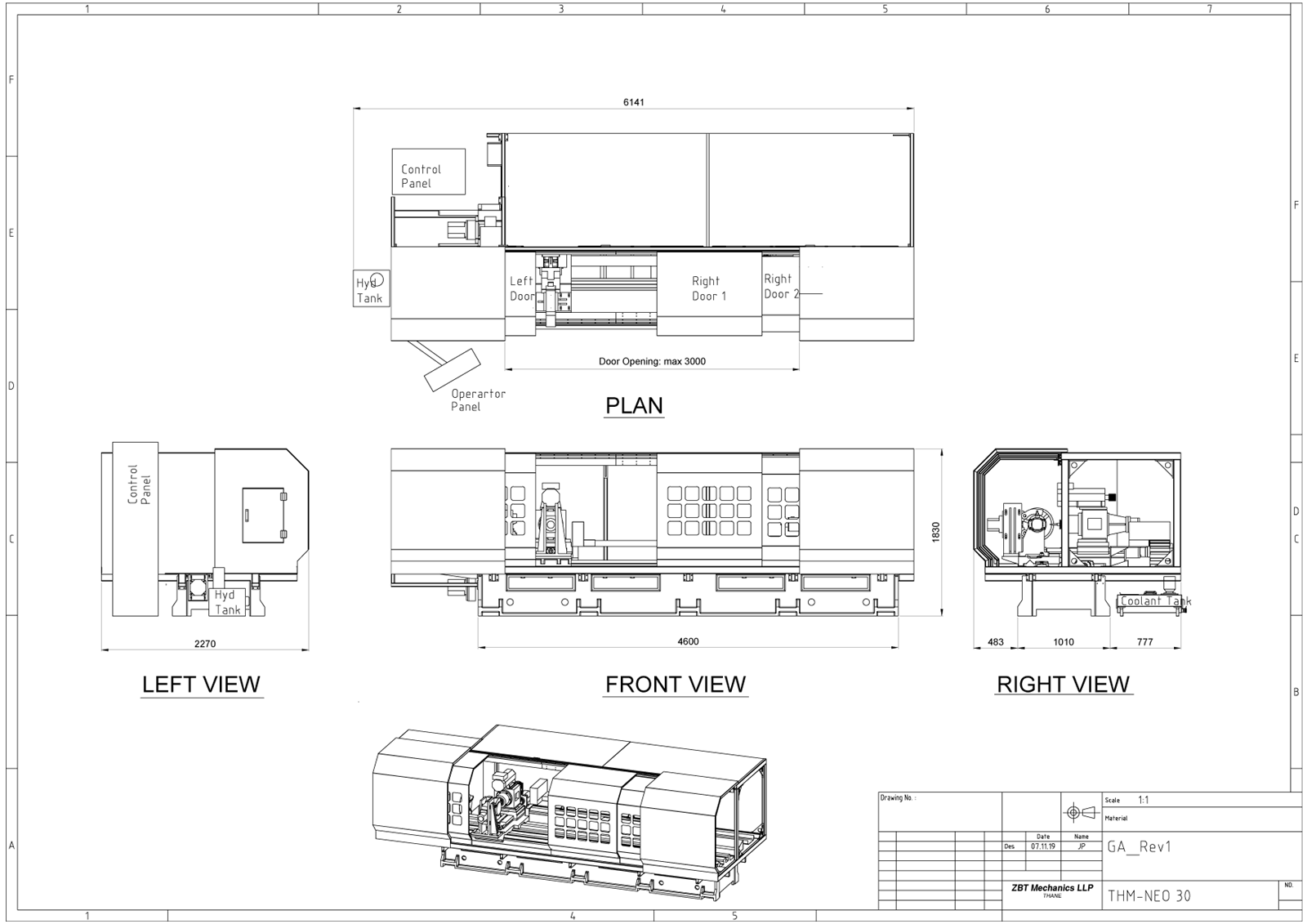

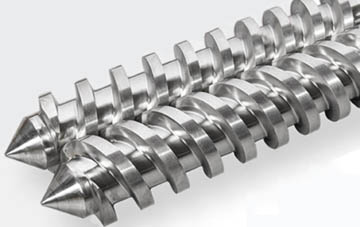

THM-NEO series is the latest iteration of thread milling machines used for manufacturing of material feed screws in Extrusion and Injection moulding machines.

It is specially designed for machining of single and twin material feed screws in cylindrical and tapered profile.

Design Features of THM-Neo Series of Horizontal Thread Milling

- Flexible options with 3 servo (2 linear + rotary) or 4 servo (3 linear + rotary) axes with horizontal milling spindle configurations to suit various jobs and aimed at providing optimal cost-effective solution.

- FG260 grade Cast iron bed with 4 guide ways for excellent rigidity

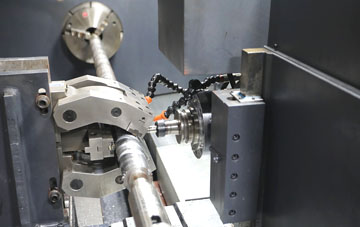

- Horizontal Milling spindle with BT50 taper and hydraulic tool clamping for easy change.

- Workpiece rotary drive is implemented using high precision rotary axis design using 2 pairs of preloaded angular contact bearings in tandem with self-aligning bearing support at rear for excellent thermal expansion characteristics.

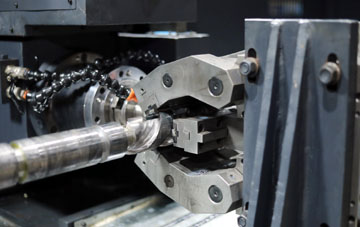

- Workpiece supported with the help of 3-jaw traveling Steady with self-centering mechanism to balance cutting forces

- Hydraulic Tailstock with dead center mounted on slide with rigid base clamping manual mechanism

- Feed axes designed using precision Rolled ball screws with high precision angular contact Ball bearing. All sliding surfaces use wear resistant Bi-plast instead of regular turcite for long life expectancy

- Innovative chip evacuation using collection trays. Optionally, chip conveyor can be incorporated as per customer requirement

- Full enclosure to ensure operator & process safety in accordance with Fire & Safety regulations

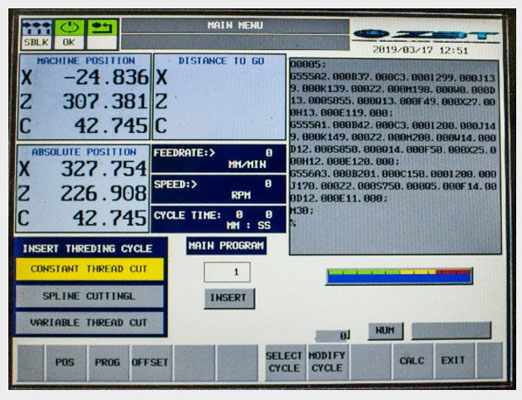

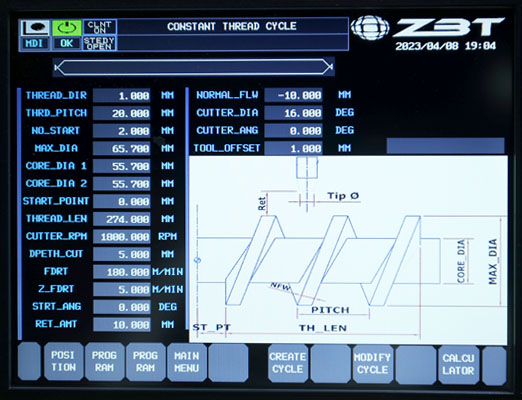

- Fully CNC controlled with state-of-the-art FANUC system

- Customized screens for easy work piece machining programs with multi-start, multi-zone feed screws with various profiles. Easy graphical representation with parameter entry makes the screw cutting process operator friendly.

- Robust and maintenance friendly system with on screen diagnostic functions, preventive maintenance information, Industry 4.0 connectivity features, capable of Remote diagnosis and IoT connectivity with higher rung networks and data transfer.