VRS Series

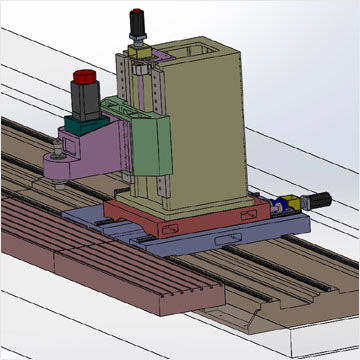

VRS series of machines are conceptualised on Floor milling configuration. The series is most suited for railway track rail machining with profile cutters demanding high torque – high rigidity machine configuration. The fixed bed configuration offers the space savers advantage over moving bed machines like planomillers.

The machine in essence, is 3-axis machining centre with high-torque spindle head and constructed using cast-iron structure. The machine is equipped with Roller type LM guides mounted on cast-iron structure which offers excellent rigidity and suitable for high feed cutting.

The major application of the series covers Tongue Rail machining from stock rail, head machining of ZU-60 rail for high speed rail networks. The machines can optionally be equipped with Electromagnetic clamping system specially designed for Indian rail standards such as ZU-60 or UIC-60kg rails and offers excellent ergonomics and easy change over of jobs.

Design Features of VRS Series

- Machine design based on Floor milling concept

- Fully CNC controlled 3 servo axes + 1 spindle configuration with high torque spindle motor suited for heavy machining of Tongue rial machining with specially designed Profile cutters.

- FG260 grade Cast iron bed with LM Guides

- Heavy duty Milling head with BT50 taper and hydraulic tool clamping for easy change.

- Provision for Electromagnetic clamping system suitable for 60kg standard rails

- Space saving design with moving column configuration.

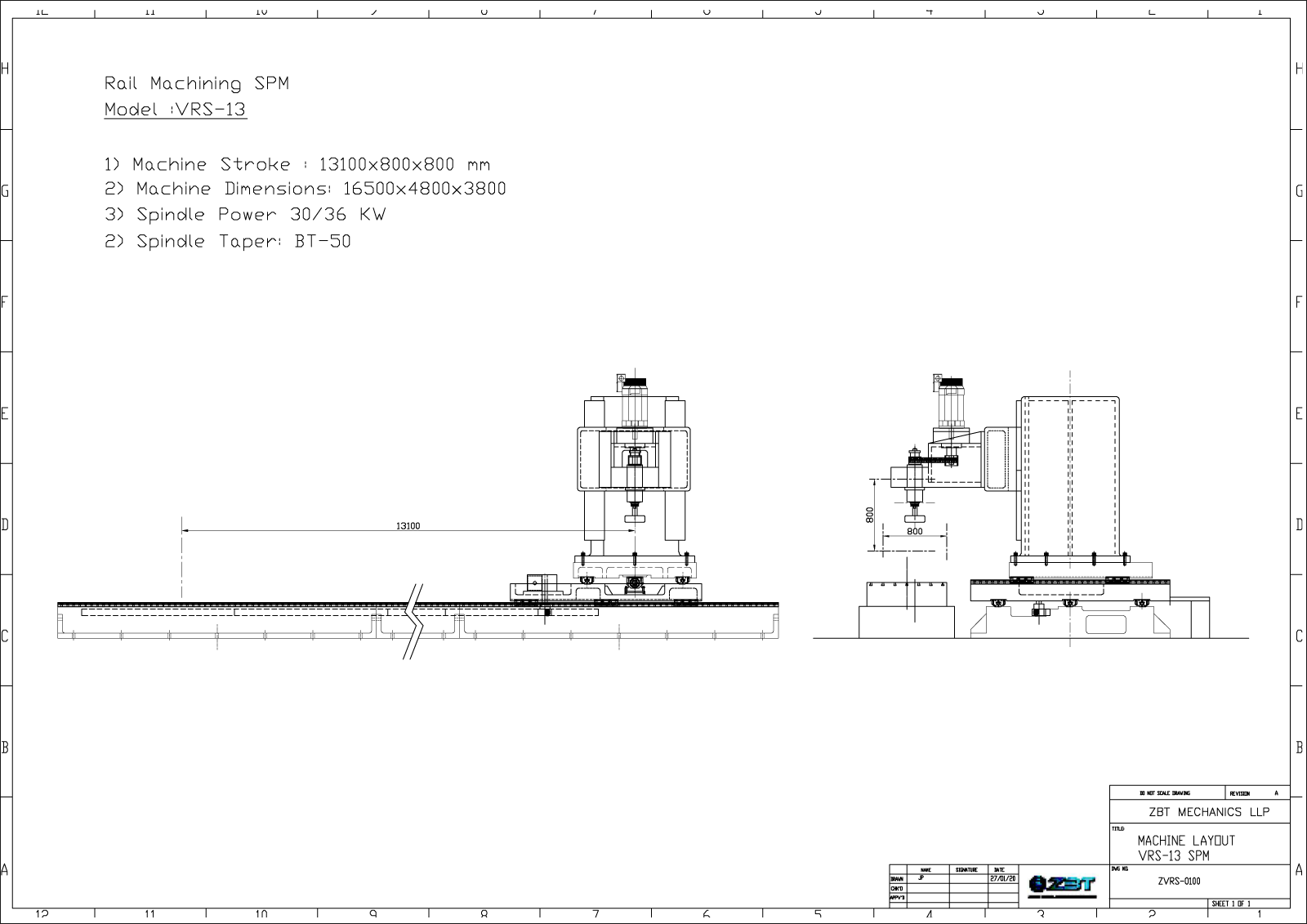

| Track Machining VRS Series (Column Travelling Floor Milling Type) |

||

| MODEL | VRS-8 | VRS-13 |

| Machine Configuration | Vertical head with 3 Servo Axes + 1 Spindle | |

| Machine Type | Column Travelling Floor Milling | |

| Control Type | Fanuc CNC with 10.4” Colour LCD | |

| M/c construction | Cast Iron | |

| M/c Axes | X & Y Axes on LM Guides, Z Axis on Box Guides | |

| Machine Stroke | 7500 x 750 x 750 | 13100 x 750 x 750 |

| Table Size | 8000 x 1000 | 16000 x 1000 |

| Column (X-axis) Drive | Rack & Pinion with Gearbox | |

| Cross(Y-axis) & vertical (Z-Axis) Drive | Ball Screw with angular contact bearings | |

| Max. Cutting Feedrate | 5000 mm/min | |

| Max. Rapid Rate | 8000 mm/min | |

| Milling Spindle | BT-50 with hydraulic Tool Clamping | |

| Spindle Motor Power | 30 / 37 Kw | |

| Cutting Force | < 1400 N | |

| Spindle RPM | 10-1800 rpm | |

| Job Holding | Electromagnetic Rail Clamping System (optional) | |

| Guarding | Semi Enclosure for cutting area | |

| Programming | ISO G-code, compatible with CAM software | |

| Power Requirement | 415V 3Ph Max. 75 KVA | |

| Coolant System | Air blow | |

| Floor Size | 8500 x 4800 | 16500 x 4800 |

| Apprx Weight | 51,000 Kg | 62,000 Kg |