PMR Series

PMR series of machines are conceptualised on robust Plano Miller configuration. The design incorporates the inherent advantage of moving table creating high inertia of motion for super heavy cutting but, in a smaller scale adapted for long products like railway track rails.

The machine in essence, is 3-axis machining centre with high-torque spindle head and constructed using cast-iron structure. The design incorporates hardened bed ways which effectively offer longer life and easy maintainability and prolonged life in heavy cutting applications. Optionally, the machines can be Offred with LM guides for medium duty applications as per customer requirements.

The major application of the series covers Tongue Rail machining from stock rail, head machining of ZU-60 rail for high speed rail networks. The machines can optionally be equipped with.

Design Features of PMR Series

- Machine design based on Plano Miller concept which offers stable heavy duty cutting performance in demanding applications using profile cutters. Large depth of cut in radial engagement with Profile cutters in turn result in optimum cycle time reduction and surface finish

- Fully CNC controlled 3 servo axes + 1 spindle configuration with high torque spindle motor suited for heavy machining of Tongue rial machining with specially designed Profile cutters.

- FG260 grade Cast iron bed with LM Guides

- Heavy duty Milling head with BT50 taper and hydraulic tool clamping for easy change.

- Provision for Electromagnetic clamping system suitable for standard rails

- Tooled up solution can be offered with job prove-out for specific products like ZU-60 or UIC-60 track rails.

| Track Machining PMR Series (Plano-miller type with moving Bed) |

||

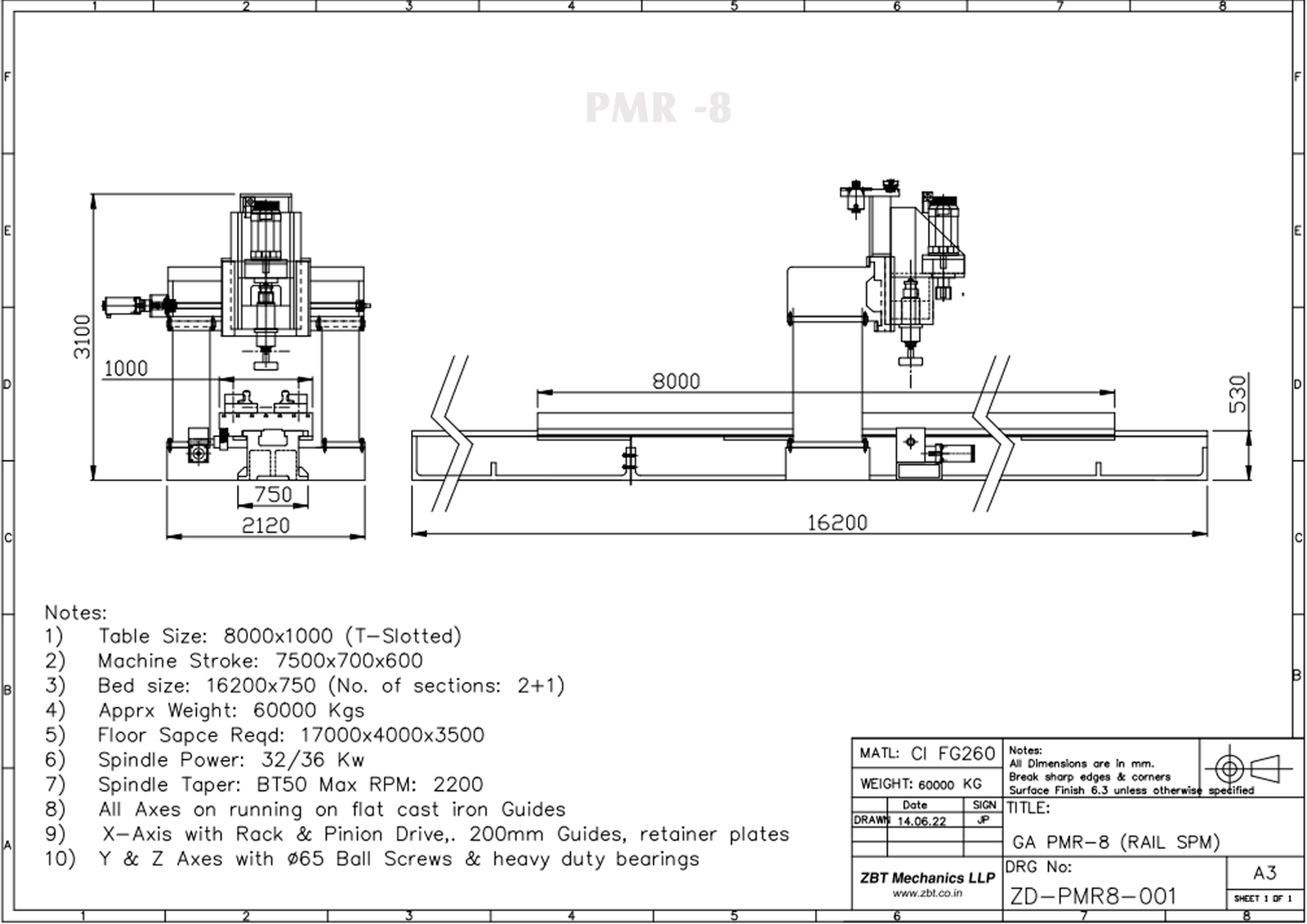

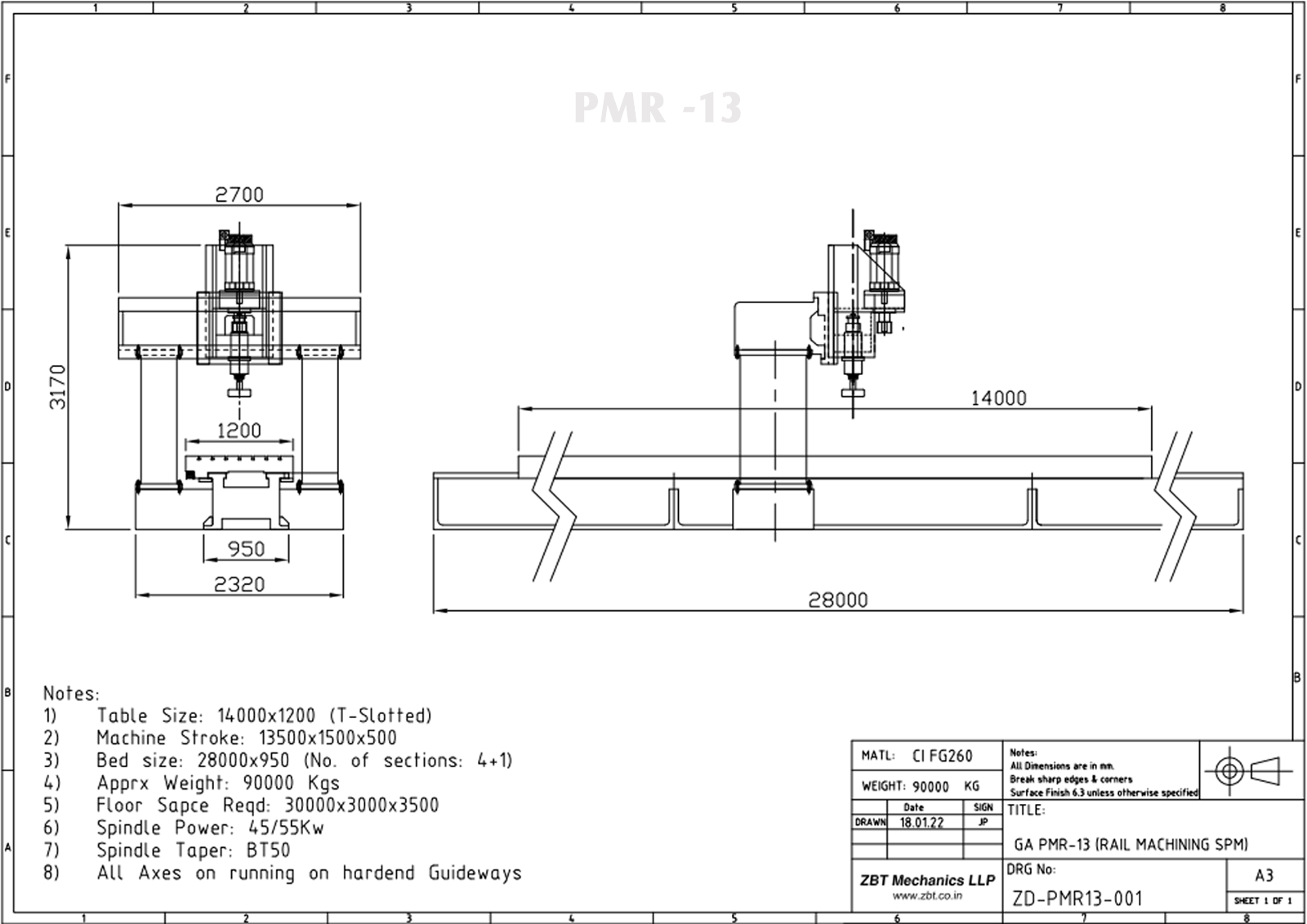

| MODEL | PMR-8 | PMR-13 |

| Machine Configuration | Vertical head with 3 Servo Axes + 1 Spindle Planomiller Type with fixed Gantry | |

| Control Type | Fanuc CNC with 10.4” Colour LCD | |

| M/c construction | Cast Iron. all axes with heavy duty Box Guides | |

| Machine Stroke | 7500 x 700 x 500 | 13500 x 1500 x 500 |

| Table Size | 8000 x 1000 | 14000 x 1200 |

| Table (X-axis) Drive | Rack & Pinion with Gearbox | |

| Cross(Y-axis) & vertical (Z-Axis) Drive | Ball Screw with angular contact bearings | |

| Max. Cutting Feedrate | 5000 mm/min | |

| Max. Rapid Rate | 8000 mm/min | |

| Milling Spindle | BT-50 with hydraulic Tool Clamping | |

| Spindle Motor Power | 45 / 55 Kw | |

| Cutting Force | < 1400 N | |

| Spindle RPM | 10-1200 rpm | |

| Job Holding | Precision Angular contact Ø100 | |

| Spindle Bearings (Rear) | Electromagnetic Rail Clamping System | |

| Guarding | Semi Enclosure for cutting area | |

| Programming | ISO G-code, compatible with CAM software | |

| Power Requirement | 415V 3Ph Max. 75 KVA | |

| Coolant System | Air blow | |

| Floor Size | 6100 x 2500 | 7200 x 2500 |

| Apprx Weight | 61,000 Kg | 92,000 Kg |