VTM Series (4 Axis Vertical)

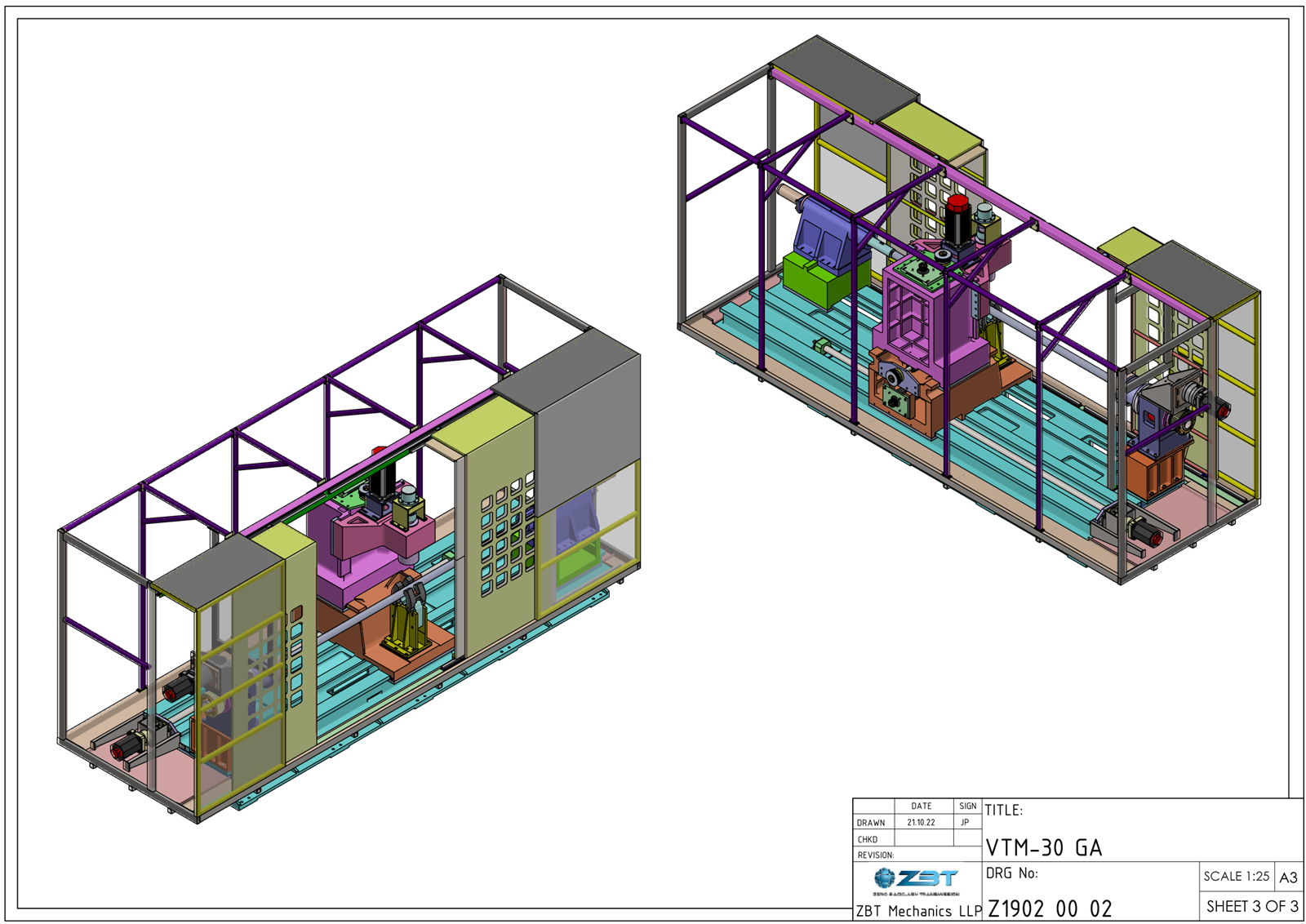

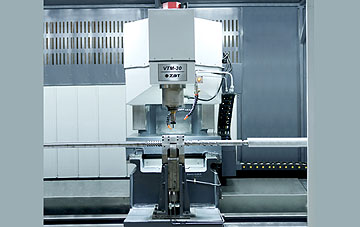

VTM series is the optimally reconfigured version of popular THM series of Thread milling machines. It is ergonomic for machining and optimal chip removal which results in improved surface finish of single and twin material feed screws in cylindrical and conical profile.

Salient Features of VTM Series Thread Milling SPMs

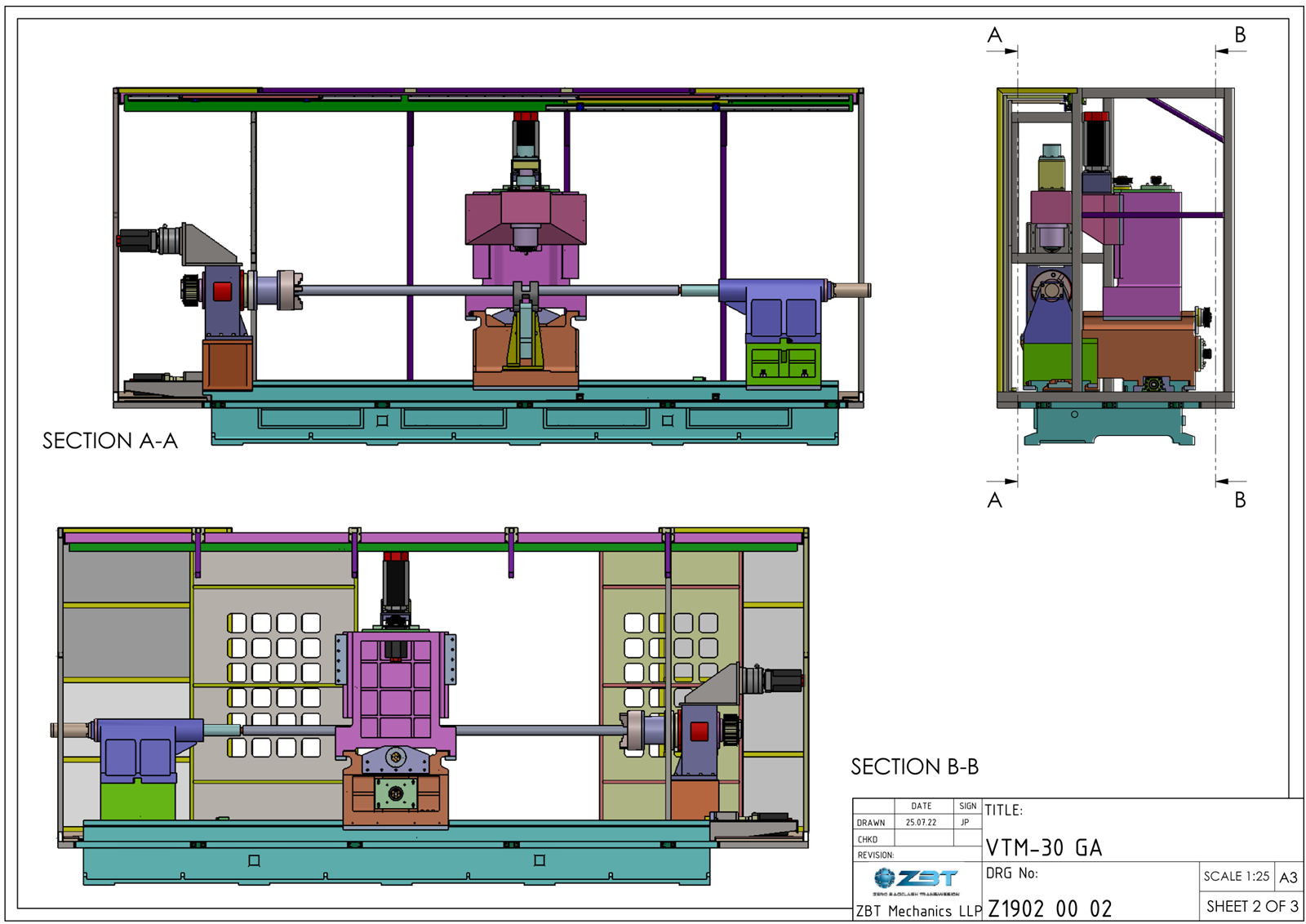

- 4 servo (3 linear + rotary) axes with vertical milling spindle setup.

- FG260 grade Cast iron bed with 4 guide ways. X axis slide is designed with unique & functional step bed with adequate base width to support the vertical structure.

- Vertical spindle design ensures optimum chip removal. Low working height of machine Base enabling direct view of the cutting process to reduce operator fatigue and improve productivity.

- Vertical milling spindle with BT50 taper and hydraulic tool clamping for easy change.

- Machine is designed with coolant tank integrated in the bed

- Custom screens for Screw cutting programs with graphical representation.

- All other features of THM Neo series are carried over ……

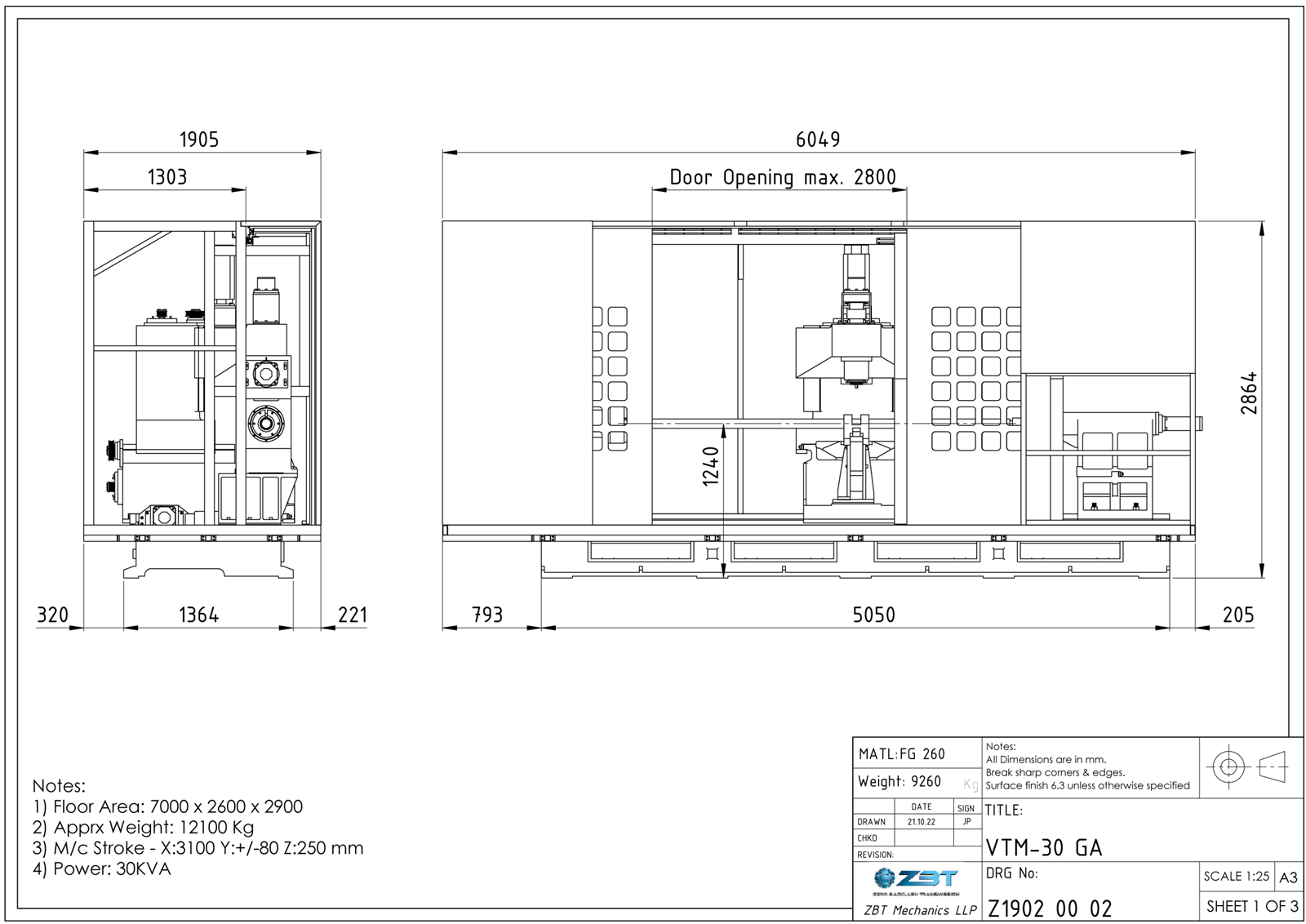

| Screw Machining Series VTM Series (Vertical Series – 4 Axis Configuration) |

||

| MODEL | VTM-30 | VTM-40 |

| Machine Configuration | Vertical with 4 Servo Axes + 1 Spindle | |

| Control Type | Fanuc CNC with 10.4” Colour LCD | |

| M/c construction | Cast Iron (FG260) 4 Flat Guides with Bi-plast Antifriction Layer, Hand Scrapped | |

| Max. Admissible Job Size | Ø180 x 3000 | Ø180 x 4000 |

| Longitudinal (X-Axis) Axis Stroke | 3100 | 4100 |

| Cross (Y-Axis) Stroke | +/- 90 | |

| Vertical (Z-Axis) Axis Stroke | 250 | |

| Rotary (A-Axis) Axis Stroke | Continuous Rotary with Infinite Rotations | |

| Max. Cutting Feedrate | 6000 mm/min | |

| Max. Rapid Rate | 10000 mm/min | |

| Milling Spindle | BT-50 with hydraulic Tool Clamping | |

| Spindle Motor Power | 7.5/11 Kw | |

| Spindle RPM | 10-2400 rpm | |

| Spindle Bearings (Front) | Precision Angular contact Ø100 | |

| Spindle Bearings (Rear) | Precision Angular Contact Ø85 | |

| Job Holding | Mechanical Chuck Ø250 3-jaw self-centering | |

| Tailstock | Hydraulic operated with dead center | |

| Support Mechanism | Self-centering hydraulic Steady Rest with Guide Pads | |

| Guarding | Full Enclosure | |

| Programming | ISO G-code, compatible with CAM software | |

| Customised Cutting Cycles | Conical & Cylindrical muti-start, multi-zone screw Milling cycles with Graphical Representation | |

| Power Requirement | 415V 3Ph Max. 30KVA | |

| Coolant System | Emulsion / neat oil Tank integrated in the Bed | |

| Floor Size | 6100 x 2500 | 7200 x 2500 |

| Apprx Weight | 12,500 Kg | 13,500 Kg |